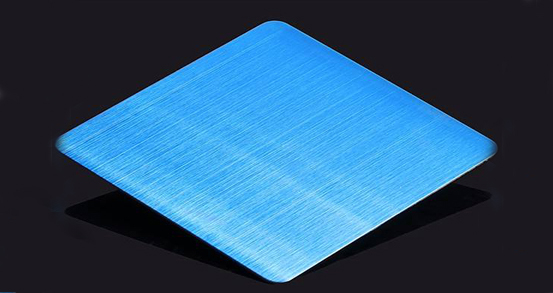

For a long time, colored stainless steel sheets have been polished by mechanical polishing, electropolishing, and chemical polishing to obtain a bright and scratch-free mirror effect.

What is the mechanical polishing process for colored stainless steel sheets? Let me introduce it below!

Mechanical polishing refers to polishing a colored stainless steel plate on a special polishing machine, which is mainly composed of an electric motor and one or two driven polishing disks. The polishing disc is supplemented with a polishing cloth of different materials. Canvas or tweed is often used for rough throws. Flannel, fine or silk for fine polishing.

The polishing liquid is continuously dropped on the polishing plate during polishing, or a polishing liquid made of very fine diamond powder is applied to the polishing plate. When grinding, the surface of the sample should be pressed evenly to the rotating polishing disk. The pressure should not be too great, otherwise irregularities, deformation marks will be formed on the surface of the colored stainless steel plate, and will continue to reciprocate radially to the center along the edge of the disk. A sharp mirror is obtained by the relative grinding and rolling action between the fine polishing powder (liquid) and the abrasive surface to obtain a bright mirror.

Mechanical polishing features: low cost, simple operation, but low efficiency, uneven polishing surface, difficult to master polishing time, suitable for small area treatment.

For more information on the processing of color stainless steel plates, please visit: https://www.meibaotai.com

Post time: May-14-2019