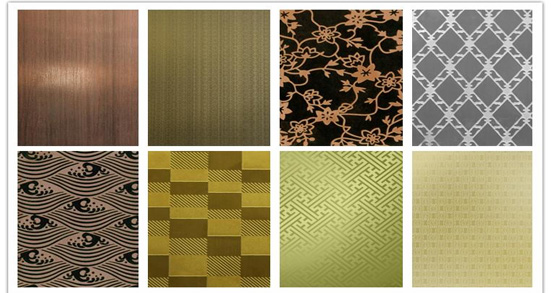

The process principle of stainless steel etching plate is: the use of strong oxidation of ferric chloride, the surface corrosion of stainless steel, ferric iron into a relatively stable ferric iron;The specific production process is: first on the surface of stainless steel coated with anticorrosion layer, will need to protect the part of the protection, put it into the spraying line of ferric chloride, corrosion will be washed off the anticorrosion layer, the formation of patterns.

The key steps of stainless steel etching plate production is the surface coating and corrosion process.

The corrosion protection layer of the etched stainless steel plate is generally made of special ink.The printing ink process according to the output and production costs can be divided into two kinds, one is suitable for the production of uniform pattern and production of large quantities of products, called screen printing.Designers in accordance with the pattern to be produced in a 1:1 ratio of the standard screen, and then the screen printing machine on the surface of the steel plate to brush ink protective layer.The other is film sensitization, which uses the high-precision characteristics of film to make patterns on the surface of steel plates.There is little difference in quality between the two methods, mainly due to the cost of production.

Post time: Mar-15-2021